Applications

The sproket and segment can be used as the after selling service parts for most of the famous excavator and bulldozer brand such as KOMATSU, CATERPILLAR, HITACHI, KOBELCO, SUMITOMO, KATO, HYUNDAI, DAEWOO, DOOSAN, JCB, SHANTUI etc.EXCAVATOR

| PC20A(DL) | PC20B(DL) | PC20-7 | PC20-7(DL) | PC20-7(A6)9 hole | PC20-7(A6)18 hole | PC30-7 | PC40 | PC50 |

| PC50UU-2(APS) | PC60-1 | PC60-5 | PC60-5(VGM) | PC60-6 | PC100-3 | PC100-5 | PC100-5(BPT) | PC100-5 |

| PC100 | PC175 | PC200-1 | PC200-3 | PC200-3(JG.东虹) | PC200-5 | PC200-5(VGM) | PC200-5(ROJC) | PC200-5(SDF) |

| PC200-5(PTSN) | PC200-7(DLM) | PC300-3 | PC300-5 | PC300-5 | PC300-6/【KM4186】 | PC360-8MO | PC400-3/5 | PC400-6 |

| PC400-7 | PC400-6(DL) | PC400-6 /【KM2384】 | PC600-6 | PC800 | PC800-6/850 | PC1250-6 | ||

| EX60 | EX60(EML) | EX60(AMH) | EX60-2 | EX60-2(RJC) | EX70(AMH) | EX70(IHE) | EX70 | EX100-5 |

| EX135US | EX150 | EX165 | EX200-1 | EX200-2 | EX200-3/5 | EX200-3/5 | EX200-3/5(STK) | EX210(SCM) |

| EX220-5 | EX255(ATT) | EX300-1(A) | EX300-3(A) | EX300-5 | EX300-5(H5) | EX400-5 | EX400 | ZX870/800 |

| EX1200-5 | ZX30U-2(H5) | ZX55 | ZX60(LHC559A1) | ZX60(LHC559A2) | ZX120-3(LHC558A1) | ZX200-3(LHC551B1) | ZX240-3 | ZX270-3 |

| ZX330-3(LHC556A1) | ZX450(LHC557A1) | EK400(GLR) | SK60-8 | E306(9hole) | E306(12hole) | PC56-7(12 hole ) | ||

| E70 | E120B | E120B(SKS) | E312 | E215 | E215(CTP) | E215BJ(H5) | E315(SKH) | E225 |

| E200B | E300B | E320 | CAT320 | E320(CEP) | E235 | E300B | E325(PRO/H1) | E32/5E330 |

| E330 | E330(CTP) | E345【CR6593】 | DH55(500)Φ15 | DH55/DX55/60Φ16 | DX80/DH80/KM3158 | DH130 | DH150【2108-1040A】DX120/140 | DH225 30hole |

| DH220-5(22孔) | JH190 (DH220-3) | DH220-3(JG22.06-3) | DH280 | DH300 | DH370【K1033717】 | DH400 | DH500 | DX225(SSK) |

| DX260LC(斗山)/S255(H8) | DX340/300 | DX370/K1033717 | DX380LC | DX420 | DX480 | CRRC160 | SWDM20(203) | SWDM22(216) |

| SWDM28山河钻机(203) | SUNWARD70 | SUNWARD70(OLD) 9hole | SWE70(17) 3HOLE | |||||

| R35Z-7(SSK) | R55-5 | R60-5 | R80 | R130-1 | R130-2 | R130-1 | R200-1 | R200-2 |

| R150-9【DL0080A011105000A】 | R220LC-9S | R225LC-7(HHI)/81EM-10012B | R250LC-7 | R275 | R290-1 | R290-2 | R300LC-7(CIA) | R305 |

| R305(北京/007) | R305(PRO/H1) | R305(VGM) | R360LC-7 | R450LC-7(H1)=EC460 | R480LC-9 | R2606 | R914 liebherr | R934 liebherr |

| HD820-1(22孔)/701070 | HD820-6(26 hole)/701071 | EC55 | EC140 | EC210 | EC210BLC(PRO/H1) | EC210(RMP) | EC240B | EC290 |

| EC290(LP) | EC360 | EC460 | EC700 | YC60 | YC85 | IS55-60 | kubota185 | FR39(YC35) |

| FR60(福田60)9孔 | JCB JS140 | JCB JS210 | JS220(H1) | JCB JS360 | UH135ZOD(VGM) | B60 | VR631200(VPE) | UH04-5 |

| SK030(9H) | SK030(18H) | SK07-1(LH) | SK07-2 | SK07-2(DH) | SK07N2 | SK045N2 | SK40SR | SK60 |

| SK60-3 | SK60-5 | SK60-6 | SK60-8 | SK55SRX/CX58 | SK75 | SK100 | SK100L | SK100L(DLM) |

| SK130L-8(JKH) | SK140-8 | SK200-3 | SK200-8 | SK250-8 | SK200-8(SSK) | SK210 | SK220-1 | SK220-3 |

| SK230 | SK300 | SK270 | SH55 | SH60(G8) | SH120 | SH120-A3(A3) | SH120-5双 | SH125X-3/SH130/CX130 |

| SH200 | SH200(DL) | SH200(H7) | SH280 | SH300(1/2) | SH340 | SH450(DL) SK460 | CX290(KSA1061) | CX360 |

| 凯斯800/870 | UH083 | UH110Z1D | UH098HOA | UH098COB | UH063-7 | UH085EOA(VGM) | UH81(BPT) | UH085T0A(VGM) |

| MS110-5 | MS180-3 | D20 | D31-15 | D31-17 | D31-17(PTSN) | D3C | D4 | D4D |

| D4D(KEE) | D4D | D4H | D4H(TTL) | D41E | D50-15 | D5B | D6 | D6D |

| D6D(ACD) | D65 | D85 | 0800759 | FL4 | FL4-2(KEE) | FL4(G2) | FL4 | FL6(KEE) |

| FL6-2#(KEE) | SE210-3 | H3(D2) | B3 | B1HD | UH04-7 | UH04-5 | UH04-5 | |

Products Specifications

Feature

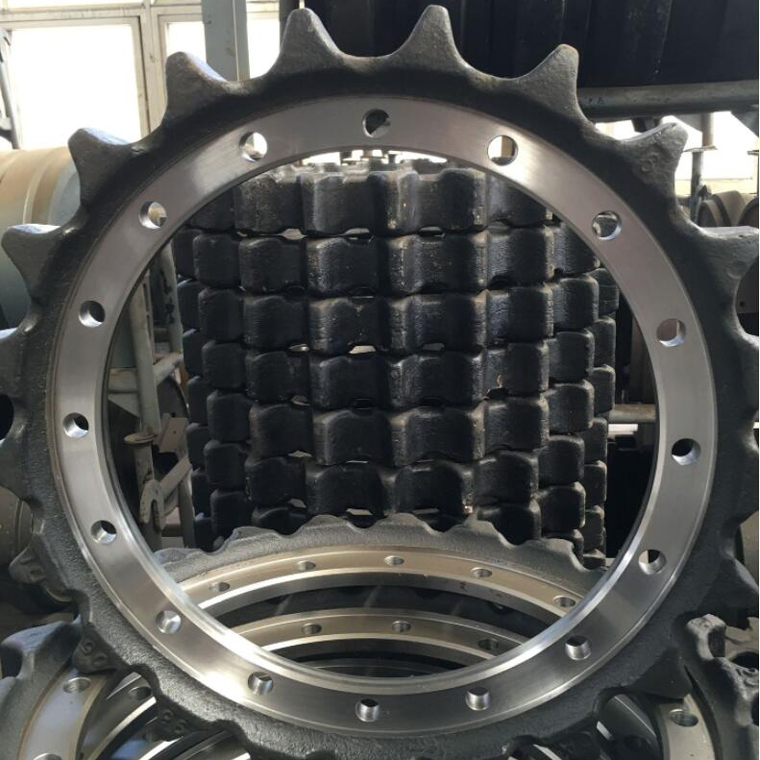

1. The sproket and segments we produced are used for a very complete range of machines, from 0.8 to 100 tons excavator and bulldozer. 2. The parts are suitable for both excavators and bulldozers. 3. The sprockets are molded or forged and subsequently processed, giving them a special heat treatment to make sure well hardness. 4. Use precision processing technology and special heat treatment technique to reach best wear-resistance and have maximum extent loading capacity as well as anti-cracking ability.Difference between sproket and segment:

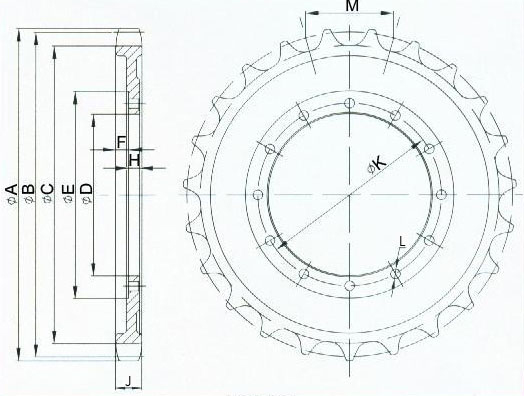

Sprockets are metal cogwheels that consist of a metal inner ring with bolt holes or a compression hub and a gear ring in one unit. Sprockets can be screwed on directly, or pressed onto the machine’s drive hub, and they are usually used for excavators. Just like sprockets, segments also consist of a metal inner ring with bolt holes and a gear ring. Unlike sprockets, segment groups exist from individual segments which make up the sprocket for the undercarriage of bulldozers. This means that the segments can be exchanged without dismantling the track link.How to confirm the size of the sproket:

For normal excavator or bullzer, the sproket and bulldozer size are standard. We can choose the sproket according to the excavator and bulldozer brand and model. If the excavator and bulldozer are unusual models or need to be cusomized, we need the following size information in the drawing to make sure we will offer right sproket.Storage