Applications

The idler can be used as the after selling service parts for most of the famous excavator and bulldozer brand such as KOMATSU, CATERPILLAR, HITACHI, KOBELCO, SUMITOMO, KATO, HYUNDAI, DAEWOO, DOOSAN, JCB, SHANTUI etc.Application for EXCAVATOR

| Komatsu (PC40-7 PC60-5-6-7 PC75 PC100-3-5 PC120-5 PC130 PC200-2-3-4-5-6-7-8 PC220-1-3-5 PC230 PC240 PC300-1-5-6-7 PC400-1-3-5) |

| Hitachi (EX40 EX55 ZX55 EX55-5B EX60-2-3 EX70(ZX70) EX100M EX100-1-2-3-5 EX120 EX150 EX160 EX200-1-2-3-5 ZX200 ZX210 EX220 ZX230 EX300-1-2-3-5 EX330 EX400 UH08 UH07 UH10 UH14) |

| Sumitomo (SH60 SH65 SH100 SH120-A3 SH120 SH200 SH220-1-5 SH260 SH280 SH300-1-2-3 SH340 SH580-5 S25 S35 S120 S160 S250 S260 S265F2 S280 S280F2 S280FA) |

| Kobelco (SK30 SK40 SK60 SK100 SK120 SK200-1-6 SK220-1-3 SK230-3-6 SK300 SK320 SK07-1-2-7 SK07N2 SK09) |

| Caterpillar (E70 E110 E120B E180 E200B E240 E300B E307 CAT311 CAT312 E320 E325 E330 E450 MS180) |

| Daewoo (DH55 DH60 DH70 DH80 DH150 DH150W DH175 DH200 DH210 DH215-7-9 DH220-3-5-7 DH225 DH255 DH258 DH280 DH300 DH320 DH330 DH340 DH370 DH400) |

| Kato (HD250 HD250SE HD400 HD450 HD500 HD510 HD550 HD550SE HD650 HD700 HD770 HD800 HD1250 HD1430) |

| Hyundai (R55 R60-5-7-9 R80 R110 R130-1-2-7 R150 R190 R200-1-2 R210 R215 R220 R225-7 R265 R290 R305 R455) |

| Volvo (EC55B EC60C EC140B EC200B EC210B EC240B EC290B EC360B EC460B EC550) |

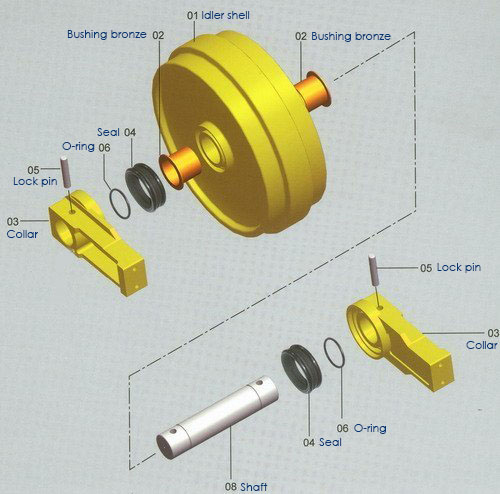

Feature

1. Good inside oil circulation system; 2. Durable wear resistant Cr-AJ alloy floating seals and flexible rubber O-rings; 3. High grade bi-metal copper bushings and high grade raw material ; 4. Use precision processing technology and special heat treatment technique to reach best wear-resistance and have maximum extent loading capacity as well as anti-cracking ability.Parts Name: idler/front idle Material: 35Mn2/40Mn; Bracketing: QT450-10; Cover: 42SiMn/40Cr; Floating Seal Cover: 42SiMn; Floating seal: 15CrNiMo3; O-Ring: Rubber; Double Metal Set: CuPb10Sn10; Lubricated Oil: SAE85; Inside Hex bolt: JB/T1000-1977; Idler hardness: HRC48-58 depth 4-6mm; Colors: According to customers' requirement; Technique: Forging, casting, heating treatment; Surface Hardness: HRC53-56,deepth:7mm-10mm; Warranty time: 2000 hour; Certification: ISO9001-9002; Package: Fumigate seaworthy packingProducts Specifications